QB Cost-effective

▶ QB series is the latest generation of full intelligent wire cutting machine equipped with the core technology of WIDCS. It is the economic and practical version of QC series. This series are widely used in precision mold processing and precision parts bulk processing in small and micro enterprises.

▶ X/Y axis is driven by stepping servo motor, Taiwan linear guideway and double nut pre-tightening ball screw structure, Z axis can be manually rise and fall. Realize high reliability and high stability of processing.It also has the function of automatic wire feeding and intelligent wire tightening.

▶ Series Features:

1. The machine body and worktable are fully supported by machine center,which greatly improve the movement of the machine rigidity and reliability of the long-term use of the machine.

2. X, Y axis are Taiwan high precision linear guide rail and double nut pre-tightening ball screw, adopts synchronous belt preload transmission structure. It ensure the high precision of the machine for a long time, avoid the transmission error when moving.

3. Tightening system adopts original core technology. Dual sensor bidirectional adaptive AC servo full closed loop dynamic tension control system, which can control molybdenum wire rough cutting, trimming wire, change tension, tightening wire and large area dressing (obtained invention patent and software copyright certificate). It is the key technical guarantee of stability and consistency.

4. The wire frame adopts economical and practical high speed wire moving tuning fork structure, with cutting thickness of 400mm and has the characteristics of less number of regulating wheels and easy operation.

5. The drum adopts fully import plastic-surface guide rail and inductive reversing switch to ensure the smoothness, high precision and long-term reliability when operating the drum with high and low speed.

6. The machine castings adopt resin sand molding technology and vibration aging treatment to eliminate internal stress and keep the machine accuracy unchanged for a long time.

7. Drum bearing and all machine bearings are Japanese NSK bearing. It makes the machine finish more reliability and durability, so that ensure the long-term benefits of customers.

8. The filter system use the slow-feeding wire-cut machine filter system, which has the characteristics of high filtration precision and long service life of working fluid.

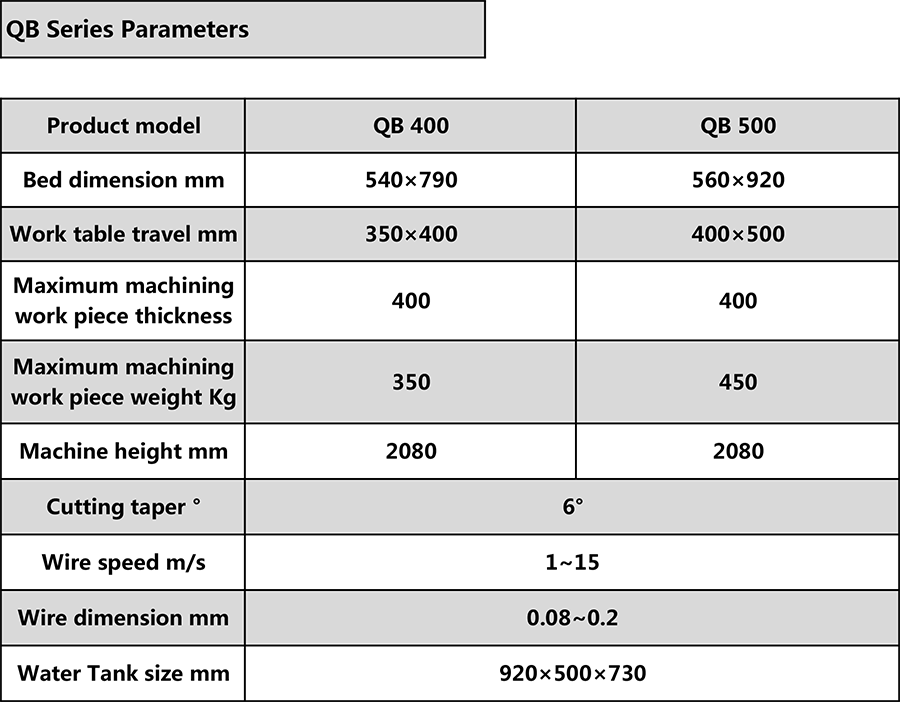

tab4